PCB levels in Hudson River water in recent days exceeded the 500-part-per-trillion (ppt) stop-dredging benchmark at Thompson Island, the northernmost water sampling point, forcing EPA to halt dredging upstream in the most contaminated zone including the area of Rogers Island at Fort Edward. EPA, however, has applied a bizarre spin on the need to cease dredging, attributing it to elevated water flow rather than to elevated PCB levels. The reality is, the General Electric Company (GE) built a pebble dam near the dredge site to slow the rate of PCB flow downstream. The reality is, PCB flow, not river flow, caused EPA to halt dredging.

By the time PCB-laden water reaches the closest water sampling points some five miles downstream of the dredge buckets, and beyond, it’s been diluted so much that the water samples come in under the 500-ppt stop-dredging benchmark that was established to protect downstream drinking water supply intakes. When the rains came, river levels rose, apparently enough to breach the pebble dam, and PCBs therefore entered the general flow, increasing PCB loads so much that downstream dilution was inadequate to reduce levels to below the benchmark. The reality is, PCB levels above the dam at Rogers Island typically must be higher… a lot higher… than the stop-dredging benchmark, but that seems okay because that’s not where water measurements are made, and it’s not where the downstream water supply intakes are located… though it is where people and homes are located. The ‘river flow’ incident is a little reminder that PCBs significantly higher than the 500-ppt stop-dredging benchmark can flow downstream, just as the low rumble you might hear at a train track should warn you that a big train is approaching.

Placement of the nearest sampling points a great distance from dredge buckets assures that actual PCB levels in water where PCBs are disturbed are not measured. The decision to measure PCB levels in water remotely from where people will be exposed suggests that close-by measurements would not be reassuring… and that maybe someone knew it when the dredging project was designed. PCBs, however, are no less toxic for being unmeasured.

Though drinking water intakes may be absent from the areas currently being dredged, PCBs in water also are known to enter the air, to a degree that can be known definitively only if air and water both are monitored where and when the dredge buckets are working. Monitoring of PCBs in air, however, also is displaced from the dredge site, a variable distance away from each dredge bucket… maybe averaging hundreds of yards. You can imagine the degree to which PCB levels decline over that distance in air by comparing the intensity of odor where a skunk sprays vs. the odor intensity hundreds of yards from the skunk. That significant reduction of odor intensity occurs because airborne concentrations of the skunk spray are reduced by air mixing with increasing distance. The reduction of concentration occurs even if the wind is blowing toward your nose but, as everyone knows, the wind blows in all directions, dispersing skunk odors and PCBs both toward and away from the nearest nose or sampling instrument.

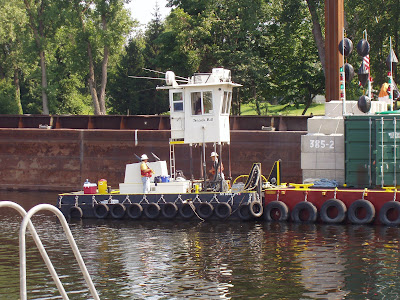

Dredging, ironically, was justified in part because of the fear that weather incidents and the occasional sinking of a boat or barge might disturb PCB-laden sediments. The clamshell dredging solution disturbs the sediments much more extremely. Dredge buckets in use in the Hudson River come in two sizes, hauling out one cubic yard or five cubic yards of sediment with each ‘bite’. The jaws, operated hydraulically, open much more widely than the width of the load that is hauled once the jaws close. Five-yard buckets open to nearly 15 feet, and close to about three feet. They are targeted to penetrate 18 inches into the sediment. When they close, 15 feet of river bottom is compressed to about three feet, causing sediment and water to billow upward as the jaws close. So, about 80 percent (12/15ths) of material initially enclosed in dredge jaws is disturbed without being removed.

If all of the billowing sediment returned to the river bottom, approximately five dredge passes on average would be required to pick it all up, approximately 20 percent each time. Of course, the river flows, and the billowed sediment flows, so the sediment returns to the river bottom downstream of where it was dredged. Computers limit dredge operations to a ‘dredging prism’, so if sediments return to the river bottom outside a dredging prism, they are not dredged again. Dredging prisms are defined by past PCB levels, not by PCB levels that result from settling of PCB-hot sediments on the river bottom downstream after disturbance by dredge jaws. According to EPA, the preponderance of river bottom in the current dredging area falls within dredging prisms… but this is not the case in most other river areas where PCB hotspots are designated for dredging.

Dredging is deemed complete at a dredging prism when, according to the EPA’s Quality Assurance Project Protocol, or QAPP: “an arithmetic average Tri+ PCB concentration in residual sediments of ≤ 1 mg/kg” [≤1 ppm, is attained]. Tri-plus PCB is total PCB minus the mono- and di-chlorinated PCB congeners, which EPA has estimated at about a third of total PCB… so the target levels are higher than they might seem. Target levels can be attained in two ways. One way is to mobilize the sediment, causing it to flow downstream outside the dredging prism… so success at dredging one spot is attained by dispersing the contaminants downstream. The second, intended way to succeed at PCB dredging is by removing sediments and dumping the sediment into a barge. How much occurs via the intended way, however, is unknown, because another parameter that EPA does not measure is the concentration of PCBs in the barge that ultimately is shipped to Texas for disposal of the PCB-laden dredge spoils.

One might think that PCB concentrations in barged dredge spoils are known from sampling in the river undertaken to map PCB ‘hotspots’. Arguably, we know the PCB levels in such sediments, but what we don’t know (though EPA might know it) is the fraction of dredge spoils that consist of sediments vs. solid objects such as boards, tree branches, rocks, tires, bottles, cans, and other metal objects that would not harbor much PCB. The mass of PCB shipped to Texas must be significantly less than the mass that would be estimated from PCB concentrations in sediments alone.

Shipment of dredge spoils to Texas, and disposal to a hazardous waste landfill, are expensive, consuming a sizable fraction of project costs. So, dredging represents a method of transporting not only PCBs, but also money, from New York to Texas. Texas is the home state of two presidents who together occupied the White House for 16 years during the decades-long evolution of the dredging project. The US EPA Record of Decision finally requiring PCB dredging by GE was issued in 2002, during the younger George Bush’s Administration.

In 2007 Dr. Uriel Oko and I published a fully peer-reviewed article in the Cambridge University Press journal Environmental Practice that documents massive underestimation by EPA of PCB, river, and sediment dynamics that would result in PCB entry into the atmosphere at dredge sites. The article is available at no charge at www.ramtrac.com/publications. The concerns raised in the article apparently have materialized, perhaps more severely even than we had predicted. Of course, the safety of the Hudson River dredging project as implemented currently can be assessed reliably only if proper measurements are taken to elucidate PCB levels in water and in air at dredge sites, and the relationship of the air levels to the water levels. Likewise, the effectiveness of the dredging project can be assessed reliably only when proper measurements are taken to elucidate PCB levels in dredge spoils that are sent to Texas, thereby to determine the amount removed from the river as opposed to mobilized downstream in the river. Clearly, construction of the pebble dam at Rogers Island demonstrates prior knowledge that PCB levels during dredging would be unacceptably high at dredge locations just north of the dam. Clearly, measurement of PCB in water remotely, at a closest point some five miles south of the dam, assures that such high levels would not be measured, notwithstanding the presence and potential for exposure to waterborne and airborne PCBs of unprotected residents and dredge workers.

Copyright © 2009 by The Center for Health Risk Assessment and Management, a Division of RAM TRAC Corporation